Integrated Fork Guide

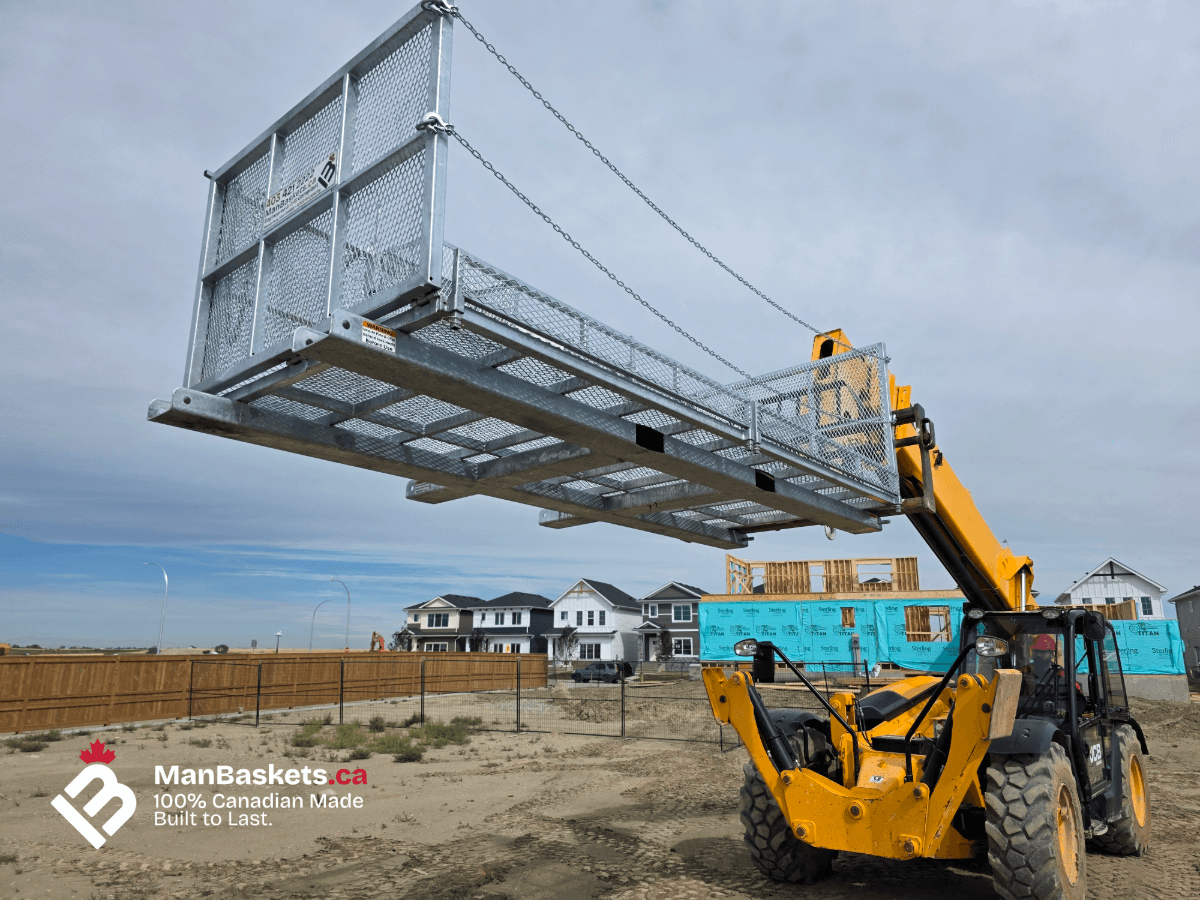

The Only Safe Way to Build a Telehandler Jib or Man Basket

When you’re working with a telehandler jib, forklift jib, telehandler manbasket, telehandler cage, or any telehandler work platform, true jobsite safety begins with proper Fork Pocket Safety.

A fully engineered Integrated Fork Guide is the only design that prevents fork drift, pin failure, misalignment, and accidental disengagement under real jobsite conditions.

Why the Integrated Fork Guide Matters

Interior view of the ManBaskets.ca Integrated Fork Guide — welded channel and engineered retention pin.

A proper Telehandler Fork Guide or Forklift Fork Guide System eliminates the most dangerous failure in any manbasket or jib: fork drift and accidental drop-off.

- Forks stay perfectly straight

- The jib or basket cannot shift sideways

- The retaining pin ALWAYS sits behind the fork heel

- The attachment stays stable even on rough ground

This is what Man Basket Fork Safety is supposed to look like.

Competitors Cut Corners — And It Shows

1) Competitors With No Fork Guide

Competitor manbasket with no Fork Guide — unsafe open pocket design.

Some manufacturers provide zero guidance inside the fork pocket.

This means:

- The forks float freely

- The cage or jib can bounce off

- No retention

- No alignment

- No compliance

This design fails OHS and OSHA immediately.

2) Competitors Who Weld Flat Bars (Thick or Thin)

Competitors weld flat bars on the sides of the fork pocket.

It does not matter if the flat bars are thick or thin — both fail for the same reason:

- Operators cannot see the edge

- Forks hit the flat bars constantly

- The bars bend, crack, or break

- The pin stops sitting behind the fork heel

- OHS/OSHA inspectors tag it Out of Service

Flat bars exist only because they are cheap and fast to weld.

They are not engineering — they are shortcuts.

| Feature / Design Element | ManBaskets.ca Integrated Fork Guide | Competitors – Flat Bar Method | Competitors – No Guide |

|---|---|---|---|

| Fork Alignment | Perfect, straight, locked-in | Weak, bends easily | Zero control |

| Safety Compliance (OHS/OSHA) | Fully compliant by design | Often fails | Fails instantly |

| Guide Construction | Full integrated welded channel | Two flat bars welded on | No guide at all |

| Durability | Industrial-grade, does not deform | Bends, cracks, breaks | Unsafe from the start |

| Pin Strength | High-grade engineered pin | Mild steel rod (bends) | Often no pin system |

| Risk of Basket/Jib Falling Off | Zero | Medium–High | Extremely High |

| Inspection Outcome | Always passes | Often fails | Fails immediately |

Our Integrated Fork Guide — Engineered, Not Improvised

ManBaskets.ca Integrated Fork Guide — engineered fork pocket with high-grade pin and clear safety labeling.

Here’s what separates our system:

- Full-Length Welded Guide Channel — a real internal Safe Fork Alignment System

- No external snag points

- Hardened, load-rated pins

- Zero drift and zero bounce

- Always passes OHS/OSHA

Why Operators Prefer Our System

Operators want:

- Straight forks

- Zero side movement

- Smooth loading

- No pin failures

- No pocket damage

- No off-center lifting

- Zero chance of the basket falling off

Our Integrated Fork Guide eliminates all of those issues permanently.

This Isn’t a Feature — It’s Mandatory Safety

If a telehandler cage, telehandler manbasket, or jib doesn’t have an integrated guide, it simply cannot be considered safe. The risks are too high.

A real Jib Fork Pocket Guide should:

- Control fork movement

- Prevent pin failure

- Prevent pocket deformation

- Ensure full retention behind the fork heel

That’s exactly what our design achieves — every single time.