How We Galvanize Our Telehandler Man Baskets, Jibs, and Work Platforms

Why We Don’t Paint — And Why Hot-Dip Galvanizing Is the Only Standard We Accept

At ManBaskets.ca, every Telehandler Man Basket, Telehandler Work Platform, Forklift Jib Boom, and Telehandler Truss Jib we manufacture is built for harsh Canadian job sites — snow, rain, mud, salt, concrete dust, forklift impact, and year-round outdoor use. In these conditions, corrosion is not cosmetic — it’s a safety risk. That’s why we don’t paint. We only use full Hot-Dip Galvanizing (HDG).

1. What Is Hot-Dip Galvanizing?

Hot-dip galvanizing (HDG) is a process where fully fabricated steel is immersed in molten zinc at approximately 815–850°F (435–455°C). As the steel is fully submerged, zinc reacts with the steel surface and forms a metallurgical alloy bond — becoming part of the material itself, not just a layer sitting on top like paint. This permanent iron–zinc alloy structure, topped with a layer of pure zinc, provides long-term, maintenance-free corrosion protection. For a deeper technical explanation of this reaction, visit the American Galvanizers Association.

2. Our Galvanizing Process for Telehandler Work Platforms & Jibs

Whether it’s a Telehandler Man Basket, a Work Platform for Telehandler, or a Forklift Truss Jib, every unit goes through the same controlled Hot-Dip Galvanizing process:

Step 1 — Initial Inspection & Preparation

We start by inspecting each unit to confirm proper vent holes, drain holes, weld preparation, and spacing between members. We design our equipment specifically to be galvanizing-friendly, so zinc can flow freely inside and outside the tubing.

Step 2 — Degreasing

Products are cleaned in an alkaline solution to remove oil, grease, and contaminants picked up during fabrication and handling.

Step 3 — Pickling (Acid Cleaning)

Rust, mill scale, and surface oxidation are removed in a controlled acid bath. This leaves clean, reactive steel ready to bond with zinc.

Step 4 — Fluxing

After rinsing, the steel is dipped in a flux solution (typically zinc ammonium chloride). This prevents re-oxidation before the unit enters the molten zinc bath.

Step 5 — Hot-Dip in Molten Zinc

The Telehandler Work Platform, Forklift Jib Boom, or Telehandler Truss Jib is then fully immersed in molten zinc. Zinc bonds to the steel both inside and outside the tubing, creating a permanent iron–zinc alloy structure.

Step 6 — Cooling / Quenching

After withdrawal from the zinc bath, the product is cooled and stabilized, either in air or in a quench tank, depending on the specification.

Step 7 — Final Inspection

We verify coating thickness and coverage according to ASTM A123 (the primary Hot-Dip Galvanizing standard) and CSA G164 (the Canadian galvanizing standard). Typical coating thickness is in the range of 75–125 microns (3.0–5.0 mils), depending on material thickness.

3. Why Galvanizing Is Essential for Telehandler Man Baskets & Jibs

Equipment like Telehandler Man Baskets, Telehandler Fork-Mount Work Platforms, and Forklift Jib Booms lives in the worst possible environment for steel — outdoor exposure, job-site abuse, and constant handling. Paint and powder-coat simply can’t keep up:

- Paint chips and flakes under impact.

- Moisture creeps under the coating and rust spreads.

- Welded joints start to corrode first.

- Structural integrity slowly degrades.

- Safety is compromised long before the product “looks” fully worn out.

Hot-Dip Galvanizing solves these problems:

- Protects both inside and outside the tubing.

- Forms a metallurgical bond that can’t peel like paint.

- Provides cathodic protection — zinc sacrifices itself before steel ever starts to rust.

- Delivers a realistic lifespan of 25–50+ years in Western Canadian environments.

- Requires virtually no maintenance.

For any attachment that carries people or lifts heavy loads, there is no responsible alternative to proper Hot-Dip Galvanizing.

4. Engineered Specifically for Galvanizing

We don’t just fabricate and “send it to the galvanizer.” Our Telehandler Man Baskets, Telehandler Work Platforms, and Telehandler Truss Jibs are designed from the start with galvanizing in mind:

- Correct vent and drain holes in all enclosed sections.

- No sealed cavities that can trap gas, acid, or zinc.

- Deburred welds to allow smooth zinc flow.

- Proper spacing between members to avoid shadowing.

- Optimized orientation for hanging and draining in the zinc bath.

That’s how we achieve consistent, full-coverage coatings that protect every critical structural component for the long term.

5. Why We Don’t Use Paint

Painting is faster and cheaper per unit — but it’s also temporary. For safety equipment like a Telehandler Man Basket or Work Platform for Telehandler, “temporary protection” isn’t good enough.

- Paint: ~25–50 µm, sits on top of the steel, chips, and allows rust to creep underneath.

- Powder coat: ~60–100 µm, harder than paint but still a surface film that can crack and allow corrosion.

- Hot-Dip Galvanizing: ~75–125 µm, metallurgically bonded into the steel with sacrificial protection.

When paint is scratched, you see bare steel. Rust starts immediately and spreads under the coating. When a galvanized surface is scratched, zinc protects the exposed steel. In simple terms: “If it scratches, it still protects.”

6. Galvanizing Time & Cost — And Why We Absorb Part of It

A typical Telehandler Work Platform or Forklift Jib Boom takes about 4–6 hours from the moment it enters the galvanizing plant until it passes final inspection. The exact time depends on:

- Size of the unit and total surface area.

- Amount of cleaning and pickling required.

- Drainage and venting complexity.

- Cooling and handling requirements.

Compared to paint — which can be applied in under an hour — Hot-Dip Galvanizing is slower, more technical, and significantly more expensive. It requires specialized facilities, energy-intensive kettles, and certified inspections. Even though galvanizing costs more than painting, we make a deliberate decision: we absorb part of the galvanizing cost from our own profit so you don’t pay a premium for a safer, longer-lasting product. Our goal isn’t to sell the most baskets. Our goal is to ensure you can use your basket, jib, or work platform for as many years as possible, with minimal maintenance and maximum safety. That philosophy is a big part of why our name is trusted in this industry.

7. Certified Galvanizing Partners Only

We work exclusively with certified galvanizing facilities that comply with ASTM A123 and CSA G164 standards. These plants provide:

- Large kettles capable of handling 12 ft and longer platforms and jibs.

- Professional racking methods to prevent distortion or twisting.

- Multi-stage quality control and coating inspection.

- Consistent thickness measurements and documented process control.

The result: durable, safe, and reliable Telehandler Man Baskets, Telehandler Fork-Mount Work Platforms, and Telehandler Truss Jibs that are built to last.

8. Final Word

Paint is temporary — galvanizing is permanent. For equipment that lifts people or heavy loads, durability and safety matter more than anything. That’s why every product we build is fully Hot-Dip Galvanized, engineered for decades of performance, and aligned with the highest galvanizing standards in North America. You’re not just buying a man basket or jib — you’re investing in safe, long-term access equipment that will keep working long after painted alternatives have failed.

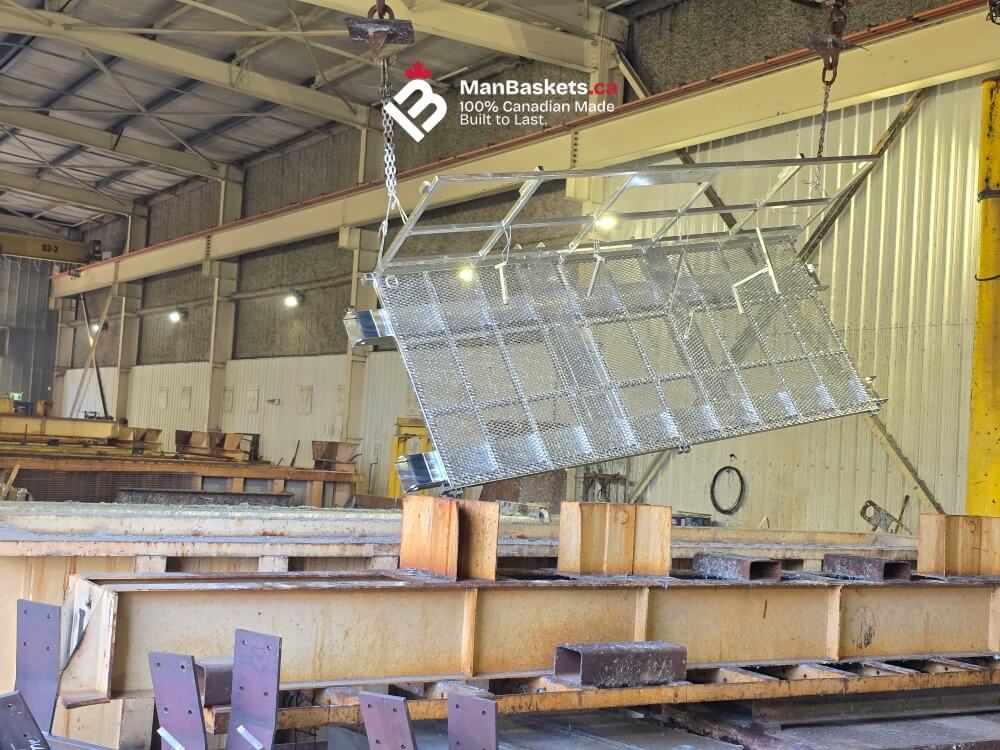

Galvanizing Photo Gallery

Here’s a look at the Hot-Dip Galvanizing process our Telehandler Man Baskets, work platforms, and jibs go through before they reach your job site.

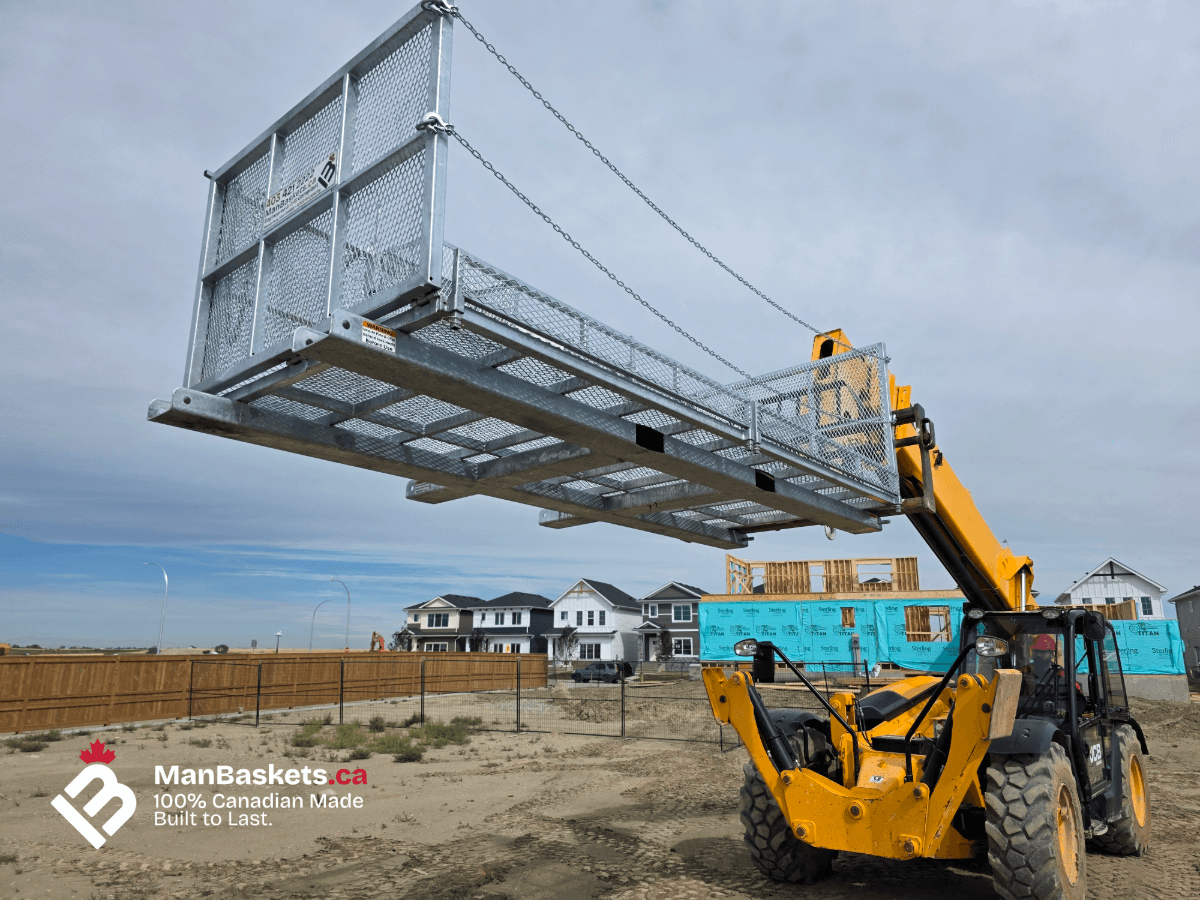

Finished Galvanized Telehandler Man Basket

Below is a completed Hot-Dip Galvanized Telehandler Man Basket, ready for years of heavy-duty use in tough Canadian conditions.

Video: Hot-Dip Galvanizing Process

Watch how our Telehandler Man Baskets, jibs, and work platforms go through the complete Hot-Dip Galvanizing process from start to finish.