Heavy-Duty 5×12 Telehandler Man Basket Delivered Same Day

Heavy-Duty 5×12 ft Galvanized Telehandler Man Basket

This project features a Heavy-Duty 5 × 12 ft Telehandler Man Basket,

fully hot-dip galvanized and engineered for demanding construction and framing environments.

The basket is equipped with fold-down side extensions, allowing the platform

length to increase by approximately 7 ft, expanding the total working length

to nearly 19 ft when deployed. This extended platform reduces the need to

reposition the telehandler, improving efficiency while maintaining safety and stability.

Built with heavy-duty, fully welded steel construction, this unit is rated for a

6,000 lb capacity and designed for real job-site use—not just showroom specifications.

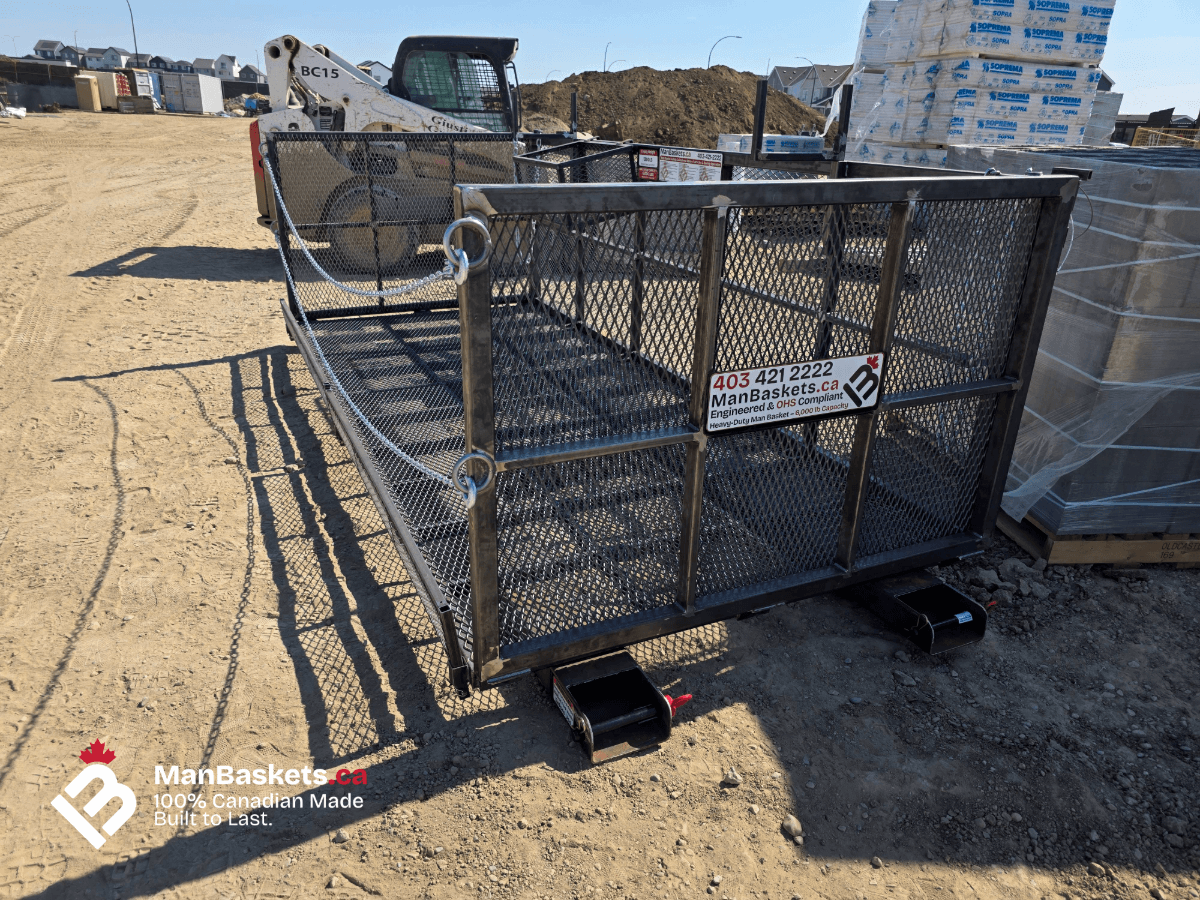

Fabrication Stage – Before Galvanizing

These images show the man basket during the fabrication stage, before hot-dip galvanizing.

At this stage, all structural components—including fork pockets, floor framing, and side

structures—are fully welded and inspected before final finishing.

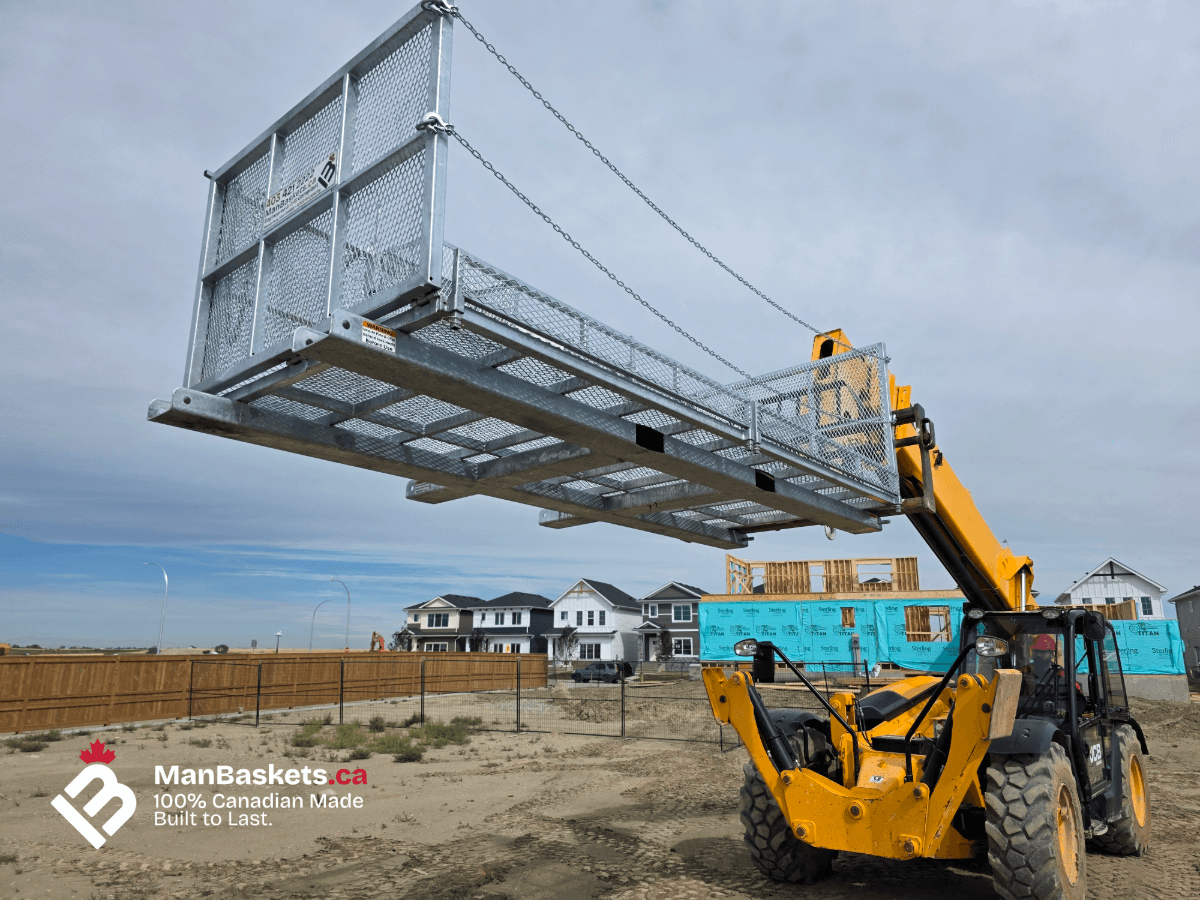

Fully Galvanized & Delivered Unit

After fabrication, the basket was fully hot-dip galvanized to provide long-term corrosion

resistance. The finished unit was delivered ready for immediate use, with proper fork pocket

geometry, reinforced floor mesh, and fold-down side extensions clearly visible.

Why This Customer Switched to ManBaskets.ca

When delivering this Heavy-Duty man basket, we noticed the customer already had another man

basket on site from a different supplier. We asked why they decided to purchase from us despite

already owning a unit.

The customer explained that the previous basket was purchased several months earlier

based purely on a lower price. After payment was made, it took nearly

two months of repeated follow-ups before the unit was delivered. In addition,

significant shipping costs were involved.

Competing Man Basket Observed on Site

Once the basket arrived, serious problems became immediately apparent. The

telehandler fork pockets were incorrectly sized, making fork insertion difficult

and preventing proper placement of the locking pins.

After repeated complaints, a temporary fix was attempted by welding an additional plate

inside the fork pocket. This created a more serious issue: when inserting the forks,

instead of sliding into position, the basket would push backward, making proper

engagement unsafe.

Further inspection revealed that the floor mesh was light-duty and flat, offering

poor traction and increasing the risk of slipping—especially in real job-site conditions.

At that point, the crew completely lost confidence in using the basket.

Immediate Availability Made the Difference

Frustrated with delays, safety concerns, and unresolved issues, the customer decided to purchase

a Heavy-Duty 5×12 Man Basket from ManBaskets.ca.

Unlike their previous experience, this unit was available in stock.

The order was placed, and the basket was delivered the same day.

ManBaskets.ca Unit in Active Use

As shown in the photos, the basket was put into service immediately after delivery.

The fold-down side extensions, proper fork pocket design, reinforced non-slip floor mesh,

and overall build quality restored confidence for the crew and allowed work to continue

without interruption.

Project Summary

This project highlights the real difference between a price-driven product

and a properly engineered Heavy-Duty Telehandler Man Basket.

Correct fork pocket geometry, reinforced anti-slip flooring, structural integrity,

and immediate availability are not optional features—they are essential for safety,

productivity, and trust on site.