What Is a Heavy-Duty Telehandler Man Basket?

Heavy-Duty Telehandler Man Baskets Engineered for Real Work — Not Just Compliance

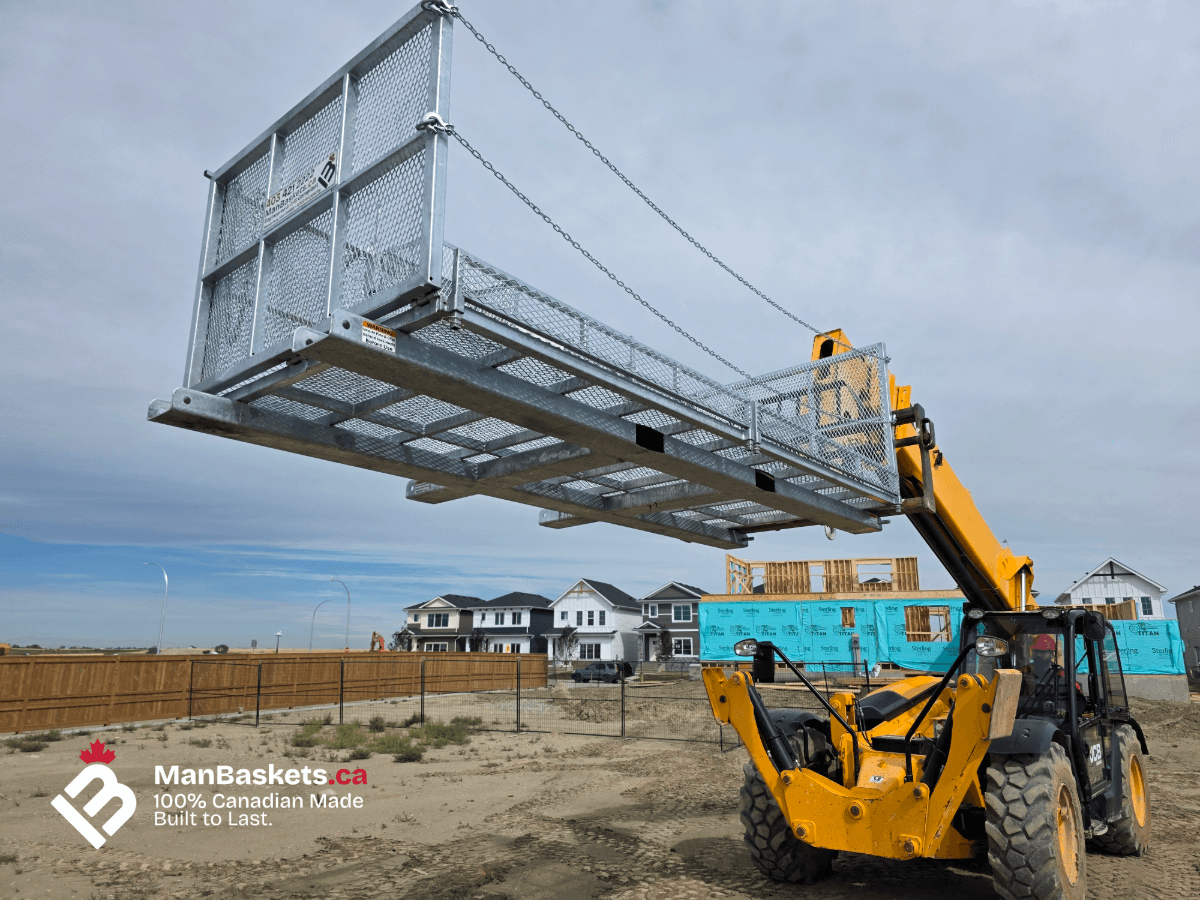

If your crew is working at height with a telehandler, the work platform cannot be an afterthought. A heavy-duty telehandler man basket is not just about meeting minimum rules—it must behave like a true, predictable, and safe personnel work platform under real job-site conditions.

At ManBaskets.ca, our heavy-duty telehandler man baskets are fully engineered, P.Eng-stamped expandable work platforms designed for real industrial use across Canada—not just for minimum CSA / OHS compliance.

Need a real work platform—fast?

Stop gambling with improvised baskets and “heavy-duty” marketing labels. If your platform is lifting people every day, it must be engineered, documented, and predictable under load.

Send us your required basket size and telehandler model. We’ll respond with pricing, lead time, and a complete P.Eng-stamped documentation package your safety team can review immediately.

View Heavy-Duty Models & Pricing | Request a Quote (P.Eng-Stamped)

What Is a Heavy-Duty Telehandler Man Basket?

A heavy-duty telehandler man basket (also referred to as a telehandler work platform, zoom boom man basket, or man basket) is a purpose-built steel platform designed to safely lift personnel for elevated work tasks using a telehandler or forklift.

Unlike light-duty or improvised platforms, a heavy-duty telehandler man basket is intended for regular use in construction, industrial, and maintenance environments where workers are standing, moving, and performing tasks while elevated. In these applications, the platform must behave as a stable and predictable work surface—not just a lifting accessory.

Heavy-duty telehandler man baskets are typically used for:

- repeated lifting cycles where platform rigidity and load behavior matter

- operation on active construction and industrial job sites with uneven conditions

- use under CSA and OHS requirements across Canadian jurisdictions

In practice, the difference between a standard man basket and an engineered personnel platform becomes apparent during daily use—how the platform responds to movement, loading, and repeated lifting cycles over time.

Designed as a True Work Platform — Not Just a Basket

Many products are labeled “heavy duty” simply because thicker steel is used. We start from a different question:

If workers are standing, moving, and actively working on this surface, will it behave like a solid, predictable floor?

That principle drives every structural and safety decision in our design. The result is minimal flex under load, predictable behavior over time, and confidence for operators, supervisors, and site safety personnel.

Structural Steel Throughout — No Weak Zones

We use 2×2 and 1×2 structural steel tubing throughout the entire basket, not only in selected or “reinforced” areas.

- uniform rigidity across the full platform

- proper load distribution with no soft spots

- reduced localized flex and long-term distortion

The basket stays square, stable, and predictable after years of lifting cycles.

Zero-Twist Base and Reinforced Fork Pockets

Under every fork pocket, full-length 4×8 × 0.188 steel tubing runs across the base.

- safe lifting from either side

- reduced torsional twist under load

- improved long-term shape retention

This is one of the most significant structural differences between these platforms and lower-quality alternatives.

Learn more about the fork engagement approach here:

https://manbaskets.ca/integrated-fork-guide/

Engineered Load Capacity — 100 lb / sq.ft

All industrial-grade work platform models are engineered and stamped for a working load of 100 lb per square foot across the entire platform, as specified by the professional engineer.

Load Capacity Table (100 lb / sq.ft)

| Man Basket Size | Platform Area (sq.ft) | Rated Load Capacity (lb) |

|---|---|---|

| 4 × 8 ft | 32 | 3,200 |

| 4 × 10 ft | 40 | 4,000 |

| 4 × 12 ft | 48 | 4,800 |

| 5 × 8 ft | 40 | 4,000 |

| 5 × 10 ft | 50 | 5,000 |

| 5 × 12 ft | 60 | 6,000 |

| 5 × 14 ft | 70 | 7,000 |

| 5 × 16 ft | 80 | 8,000 |

Note: Actual allowable working load may be limited by telehandler capacity and local OHS requirements. Always follow stamped drawings and site regulations.

- 4×12 Telehandler Man Basket

- 5×12 Telehandler Man Basket

- 5×14 Telehandler Man Basket

Exclusive Expandable Side Platform System

All heavy-duty models feature integrated fold-down side platforms engineered as part of the load-bearing system—not as accessories or add-ons. This creates a true expandable work platform, not just a basket with fold-down rails.

How the System Works

- each side platform hinges at the base

- locks vertically using a custom locking T-pin

- is supported by a dual-purpose safety chain

When folded down, the side becomes fully walkable, the working length increases, and the working load transfers into the chain rather than the hinge. A controlled 1–2° slope is built into the deck to reduce hinge stress and long-term fatigue.

Extended Working Length (All Heavy-Duty Models)

| Original Basket Size | Extended Working Length |

|---|---|

| 4 × 8 ft | 4 × 15 ft |

| 4 × 10 ft | 4 × 17 ft |

| 4 × 12 ft | 4 × 19 ft |

| 5 × 8 ft | 5 × 15 ft |

| 5 × 10 ft | 5 × 17 ft |

| 5 × 12 ft | 5 × 19 ft |

| 5 × 14 ft | 5 × 21 ft |

| 5 × 16 ft | 5 × 23 ft |

Floor, Side Protection and Tool-Drop Prevention

- heavy-gauge steel mesh flooring with small openings

- full mesh side panels and full rear mesh panel

- reduced risk of tools or materials falling from height

Multiple 1×2 steel profiles installed edge-up distribute load evenly and reduce long-term sagging.

Kickboards and Fall-Protection Safety Chains

Two separate but complementary systems protect the front opening.

- two-piece kickboards to reduce foot slip and material roll-out

- two longitudinal fall-protection safety chains independent of the kickboards

Whenever the basket is lifted off the ground, both kickboards and safety chains must be installed and secured.

Fork Pocket Safety and Multiple Lifting Points

- high-strength fork pocket locking pins supplied as standard

- mandatory use every time forks enter the basket

- basket can be lifted from multiple sides to reduce repositioning

Interior view of the ManBaskets.ca Integrated Fork Guide — welded channel and engineered retention pin.

Fall-Protection Anchor Points

- three certified anchor points

- each rated at 5,000 lb

- designed for harness and lanyard connection

Finish Options — Built for Canadian Conditions

Hot-dip galvanizing is available for long-term corrosion resistance in outdoor or harsh environments.

https://manbaskets.ca/galvanizing/

Compliance Across Canada (CSA / OHS)

In Canada, the use of telehandler man baskets is governed by provincial Occupational Health and Safety regulations and applicable CSA standards. While requirements vary by jurisdiction, the expectation is consistent: platforms used to elevate personnel must be engineered, documented, and used in accordance with recognized safety standards.

Most jurisdictions expect personnel platforms to be supported by engineering documentation appropriate to the intended use, demonstrating compliance with applicable safety requirements.

Pricing, Quotes and Shipping

We ship across Canada and offer custom sizes and configurations.

If you are comparing on price alone, you are not comparing the same product. A true heavy-duty expandable work platform is not an accessory—it is a safety system engineered for real work.